Sectors

Choosing to refurbish rather than replace is a benefit for all industries, as you not only save time, but also money by using resources in the most sustainable way.Our solutions offer simple, safe and effective means thanks to the following features, which are rarely found in other products:

- In-situ repairs, which drastically reduce part removal time.

- Cold curing, which does not present the dangers of hot work.

- Ease of application, enabling repairs to be carried out on site.

Industrial Sectors

At RODATOR we are authorised distributors of BELZONA, we offer solutions for a variety of industries, including steel, pulp and paper mills, power generation, petrochemical, water and wastewater, facilities maintenance and maritime.

When equipment and structures in any industry require predictive or corrective maintenance, we analyse all the determining factors to find a unique, customised and effective optimal solution, with the aim of minimising downtime as much as possible.

Siderurgy

Belzona two-part epoxy repair composites and coatings are specifically formulated to repair and protect plant and equipment against the aggressive demands of the steel industry.

Belzona’s range of durable metal repair composites, coatings and high-temperature coatings based on epoxy materials are designed to meet the aggressive demands of the steel industry. Critical equipment is susceptible to a range of challenges such as wear caused by abrasion, erosion, corrosion, high temperatures and chemical attack.

Belzona solutions offer unrivalled performance in harsh application areas, reducing downtime and labour costs while increasing plant efficiency and ensuring environmental compliance.

Gas and liquid handling equipment

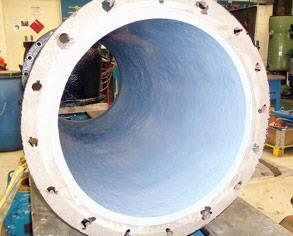

Belzona polymeric materials can be used to protect equipment against the effects of erosion and corrosion. By using compounds such as Belzona 1221 (Super E-Metal) and Belzona 1111 (Super Metal) as bonding agents, simple, cold-applied metal plate joining techniques can be used to repair damaged pipelines.

Belzona cold-curing pipe wraps can be used to solve pipeline problems and provide long-term protection against erosion and corrosion. Alternatively, the ASME PCC2 article 4.1 and ISO/TS 24817 compliant pipe wrap system, Belzona SuperWrap, can be used to restore strength to weakened or pitted metal surfaces and provide excellent corrosion protection as well as chemical resistance. Belzona solvent-free materials are widely used in other equipment such as heat exchangers, condensers and gas scrubbers. Our fast-setting emergency epoxy leak repair composites can instantly stop water or gas line leaks, avoiding potentially costly implications.

Solids Handling Machinery

Ripped, worn and broken conveyor belts due to impact and abrasion can be repaired using flexible rubber repair materials. Belzona 2111 (D&A Hi-Build Elastomer) is ideal for restoring damaged areas to their original profile and providing excellent protection against wear, impact and abrasion, without the need for vulcanisation. The versatile multi-purpose elastomers can also be used in simple, cost-effective and durable rubber repairs for equipment such as rubber rollers, spindles, bitts and hook joints on conveyor belts, as well as other rubber components.

Highly abrasion resistant composite materials, such as Belzona 1811 (Ceramic Carbide), are widely used to resist damage caused by erosion and wear on equipment such as screw conveyors, chutes, cyclones and pipe sections.

Repair and Protection of Secondary Containment Areas and Storage Tanks

Due to adverse weather conditions or condensation, moisture can accumulate in the corner of the perimeter ring or advance under the base of the tank. This can lead to corrosion problems, leaks or ultimately tank failure. Belzona offers solutions for damaged storage tanks, including emergency leak sealing and cold plate bonding, using fast-setting epoxy materials such as Belzona 1221 (Super E-Metal) and Belzona 1111 (Super Metal), which eliminate the need for hot work and reduce health and safety issues in your application. Tank bases can be sealed with our solvent-free coatings such as Belzona 3111 (Flexible Membrane), which allows trapped moisture to escape, while preventing water from entering the tank base for long-term protection.

Concrete floors and secondary containment walls can be repaired and protected using Belzona’s range of concrete repair composites and coatings, which significantly reduce downtime. Concrete repair products such as Belzona 4111 (Magma-Quartz) and Belzona 4141 (Magma-Build) are ideal for the repair and resurfacing of damaged secondary containment areas. Epoxy floor coatings, such as Belzona 4311 (Magma CR1) and Belzona 4341 (Magma CR4), are designed to provide long-term resistance against a wide range of substances, including acids and alkalis, even at high temperatures.

Shimming of worn equipment

Due to their excellent load bearing characteristics and the fact that they do not shrink, Belzona composite repair materials can be used to form excellent load bearing shims. These multi-purpose materials can be used on structural supports and machinery pedestals, as well as for the formation and shimming of wear plates, crane rails and railway tracks.

Facilities Maintenance

Belzona epoxy materials offer a cost-effective solution to maintenance problems by minimising downtime, labour and equipment replacement costs, while optimising the efficiency and reliability of facility assets. Belzona can provide solutions for the repair and protection of your facilities including the following:

- Flexible and liquid-applied roofing membranes for waterproofing buildings, structures and insulation.

- Concrete and masonry repair and protection systems

- Environmental barrier polymers to protect against and reduce environmental impact

- Safety surfacing polymers for slip prevention and to provide good adhesión

Petrochemicals

Our materials are specifically designed to provide exceptional protection against erosion, corrosion and chemical resistance in equipment operating at high temperatures and high pressure. We offer solutions with warranties of up to 20 years.

The petrochemical industry regularly faces problems such as erosion, corrosion, chemical attack, wear, abrasion and mechanical damage that cause deterioration of infrastructure and equipment over time. Instead of replacing these assets, engineers and plant managers use Belzona’s high temperature coatings and linings and epoxy-based metal repair composites for reliable, long-lasting maintenance solutions.

Our solvent-free materials offer solutions for the harshest environments and can be applied on-site to reduce downtime and labour costs by eliminating the need to replace equipment.

Deterioration of pipelines

Pipelines can suffer from erosion and corrosion, including corrosion under insulation (CUI), which can lead to leaks and loss of containment. Epoxy coatings, such as Belzona 5851 (HA-Barrier), can be applied to equipment at elevated temperatures to provide corrosion protection and prevent loss of wall thickness. In addition, Belzona offers insulation protection for pipes and other insulation equipment with Belzona 3211 (Lagseal) fire retardant, which is simple to apply and resists water and UV radiation.

Leaking pipes can be sealed in place using Belzona metal repair compounds such as Belzona 1221 (Super E-Metal) and Belzona 1111 (Super Metal). Alternatively, the ASME PCC2 Article 4.1 and ISO/TS 24817 compliant pipe wrap system, Belzona Superwrap II, can be used to restore strength to weakened or holed pipes and provide excellent corrosion protection as well as chemical resistance.

Deteriorated pipe supports due to corrosion, sliding wear and galvanic effects can lead to prolonged forced shutdowns. Belzona low temperature epoxy repair composites can be used to join new pipe supports, eliminating the need for welding.

Corrosión protection of process vesssels

Process vessels are particularly susceptible to corrosion due to the constant attack of corrosive chemical solutions and entrained solids. In addition, high temperatures and pressure, together with intensive cleaning and decontamination processes, create an aggressive corrosive environment. Distillation columns and absorption towers are also subject to a number of corrosion problems during their service life. Epoxy materials have proven to be the optimum coating solution for process vessels, providing excellent chemical, erosion and temperature resistance.

Belzona high temperature epoxy coatings, including Belzona 1391 (Ceramic HT), have a proven track record in aggressive operating conditions and are resistant to the problems associated with MEA, MDEA, sulphanol and other distillation agents.

In addition, our solvent-free epoxy coatings have resistance to explosive decompression, steam, bacteria and chemicals. The unique binary curing mechanism allows Belzona coatings to cure in service, enabling you to return equipment to service with minimal downtime.

Repair and Protection of Secondary Containment Areas and Storage Tanks

Belzona offers solutions for storage tanks damaged as a result of deterioration, corrosion and adverse weather conditions, including emergency leak sealing and cold metal bonding. Our fast-setting epoxy repair materials, such as Belzona 1221 (Super E-Metal) and Belzona 1111 (Super Metal), eliminate the need for hot work, thereby reducing health and safety issues in the application.

Tank bases can be sealed with our easy and safe to apply flexible membranes, such as Belzona 3111 (Flexible Membrane), which allows trapped moisture to escape, whilst preventing water from entering the tank base for long term protection.

Containment areas and structural supports can be repaired and protected against chemical attack using the range of concrete repair composites and coatings. Belzona 4111 (Magma-Quartz) and Belzona 4131 (Magma-Screed) are ideal for the repair and coating of damaged secondary containment areas. Epoxy coatings, such as Belzona 4311 (Magma CR1) and Belzona 4341 (Magma CR4), are designed to provide long-term protection against a wide range of chemicals, including acids and alkalis, even at high temperatures and concentrations.

Repair composites and coatings for heat exchangers

Heat exchangers are susceptible to erosion and galvanic corrosion damage due to the contact between the different metals often used in the construction of this equipment. Belzona provides a range of metal repair composites and solvent-free epoxy coatings to repair and protect heat exchangers damaged by erosion and corrosion in areas such as tubesheets, water boxes, division bars and end covers.

Our cold-curing polymeric products allow for rapid in-situ application, minimising downtime while providing long-term corrosion and erosion protection. Belzona materials are excellent electrical insulators, enabling them to prevent galvanic corrosion when insulating the dissimilar metals used in heat exchangers.

Our repair composites, coatings and high temperature coatings are suitable for other applications, including the following:

- Pump protection and repair

- Insulation protection

- Repair of conveyor belts, valves and other rubber elements

- Protective coatings and floor repair compounds

- Non-stick compounds for contact surfaces

Energy

Belzona’s epoxy coatings and metal repair composites are specifically formulated for the repair and protection of machinery and equipment in the energy sector.

Belzona’s wide range of cold-setting polymeric coatings and repair composites have been used in the energy sector for over 60 years. Our materials are designed to withstand the most demanding conditions and offer exceptional resistance to continuous wear, erosion and corrosion protection.

Belzona offers a cost-effective solution to these types of maintenance problems, minimising downtime, labour and equipment replacement costs, while increasing plant efficiency and ensuring environmental compliance.

POWER GENERATION

Flue gas desulphurisation (FGD) systems and solids handling equipment

Belzona epoxy coatings and metal repair composites can help retard the effects of erosion on solids handling and FGD systems and resist corrosion, even in areas exposed to chemicals and high temperatures. Our high build erosion resistant materials, such as Belzona 1311 (Ceramic R-Metal), Belzona 1811 (Ceramic Carbide) and Belzona 1812 (Ceramic Carbide FP), restore eroded steel, while ceramic filled linings, such as Belzona 1321 (Ceramic S-Metal), can extend equipment life.

Water cooling systems and turbines

Worn and corroded tube plates can be repaired and rebuilt using metal repair composites such as Belzona 1121 (Super XL-Metal). Our high performance epoxy coatings, including Belzona 5811 (Immersion Grade), provide excellent corrosion resistance for water boxes, end covers and tubesheets.

Cavitation-resistant elastomers, such as Belzona 2141 (ACR-Fluid Elastomer), are ideal for coating turbine gates and runners and other fluid handling equipment as they resist the impact of cavitation bubble implosion, reducing equipment degradation and subsequent operating costs.

Chemical containment areas, troughs and sumps

With the ability to be applied by brush or spray, locations such as raceways, sumps and chemical containment areas can be effectively coated to ensure long-term protection against the environment. Belzona’s wide range of epoxy coatings, such as Belzona 4311 (Magma CR1), provide resistance to a wide range of aggressive chemicals.

Pump repair and protection

Severely damaged pumps can be restored to their original profile and protected against the effects of erosion, corrosion, chemical attack and deterioration using Belzona’s range of epoxy repair materials and coatings. Low temperature curing materials such as Belzona 1221 (Super E-Metal) can be used to rebuild broken and punctured pumps by providing excellent chemical resistance.

Our range of coatings, such as Belzona 1321 (Ceramic S-Metal), offer long-term erosion and corrosion resistance, while Belzona 1341 (Supermetalglide) is proven to increase pump efficiency by up to 7% on new equipment and up to 20% on repaired equipment.

POWER DISTRIBUTION

Oil and SF6 leaks in transformers

Environmental problems can occur as a result of deterioration of old equipment leading to leaks. Belzona 1831 (Super UW-Metal) has the unique quality of adhering strongly to oily and wet metal surfaces. Depending on location, even active leaks can be stopped and sealed in place using Belzona 1291 (ES-Metal) due to its high adhesion and low temperature setting ability.

These low temperature applied materials eliminate hot work and are designed to be easy and safe to use. They are resistant to a wide range of chemicals and provide excellent corrosion protection, offering long-term solutions.

Insulator repairs

Damaged insulators can be very costly to replace. Belzona 8112 has been specially designed as an in-situ porcelain electrical insulator repair and rebuilding system. It provides excellent electrical insulating capability and offers a fast return to service solution.

Our metal repair composites and epoxy coatings are suitable for other areas within the energy sector, including the following:

- Repair of shafts, housings, keyways and other mechanical elements.

- Flexible repairs of conveyor belts and other rubber elements

- Permanent leak sealing and corrosion protection of pipelines, including active leak sealing, CUI coatings and liquid-applied insulation potting

- Maintenance and repair of installations such as liquid-applied screeds, grip systems and roofing membranes

Maritime

Belzona metal repair composites and marine coatings are specifically formulated to rebuild and protect vessels and structures in the marine sector, providing performance and reliability.

Belzona’s wide range of fast-setting, low-temperature metal repair composites and marine coatings have been used in the marine industry for over 60 years. Our products are specifically designed to withstand harsh marine conditions and have exceptional resistance against erosion and corrosion.

Providing metal repair composites to shipyards around the world, the long-term protection is proven by years of successful experience with vessels and marine structures. Our products manufactured in accordance with ISO 9001 quality management systems are approved by classification societies around the world, including the following:

- American Bureau of Shipping

- Bureau Veritas

- China Classification Society

- Germanischer Lloyd

- Korean Register of Shipping (Korean Register of Shipping)

- Russian Maritime Register of Shipping

In addition, our products have received awards from the US Navy and the UK Ministry of Defence.

Marine equipment suffers from cavitation, impact and dragging. These erosive forces destroy conventional coatings and lead to corrosion. Belzona has solutions to eliminate corrosion and reduce these erosion effects.

Rudder protection and repair

Rudders suffering from erosion and corrosion are repaired and improved using Belzona’s high quality metal rebuilding composites and epoxy coatings. Thanks to their insulating properties, our erosion resistant products stop corrosion and limit the effect of erosive forces. Cavitation is combated with Belzona 2141 (ACR-Fluid Elastomer) and Belzona 1341 (Supermetalglide) elastomer coatings.

Marine propulsion system protection and rebuilding

Marine propulsion systems vary depending on the type of container, but all suffer from the same problems. Belzona offers metal coating and rebuilding products to recover lost substrate. Protect propeller nozzles, nozzles and propellers from future attack with erosion, corrosion and cavitation resistant products.

On-site shaft repair

Shafts are under high mechanical forces and this can often cause damage. With Belzona’s metal rebuilding materials, shafts can be repaired on site with minimal downtime. Our durable corrosion prevention coatings protect fishing vessels from erosive and corrosive effects.

Engine overhaul

Engines in the marine sector specifically suffer from cooling problems and broken casings. Cavitation and corrosion occurs largely around cylinder liners and cylinder blocks. This is solved with our range of high temperature products.

Storage tank repair and protection

With approvals for potable water and high chemical resistance, Belzona can solve most storage tank problems, ranging from emergency leaks on wet and oily surfaces to chemical attack and corrosion damage.

Our metal repair composites and marine coatings are also suitable for other areas, including the following:

- Turbo springs and exhausts

- Horns

- Auxiliary diesel engines

- Alternators/generators

- Tank cleaning systems

- Oily water separators

- Steering gear

- Pumps

- Winch covers

- Lifeboats

- Access ladders

General Industry

Belzona offers a wide range of elastomeric and epoxy compounds specifically formulated for the repair and protection of equipment and machinery in general.

Belzona’s range of two-part epoxy coatings and composite repair materials have a long-standing reputation for quality and performance across a wide range of sectors.

Our cost-effective cold-curing products can be used to rebuild, repair and seal equipment damaged by erosion and corrosion, while at the same time extending equipment life, minimising downtime, reducing costly replacement costs and eliminating the hazards of hot work repairs.

Pipe repair

Cold applied and single plate joining and composite wrapping techniques (SuperWrap) can be used to repair damaged pipes with Belzona metal repair composites such as Belzona 1221 (Super E-Metal) and Belzona 1111 (Super Metal). Alternatively, the ASME PCC2 Article 4.1 and ISO/TS 24817 compliant pipe wrap system, Belzona SuperWrap II, can be used to restore strength to weakened or pitted metal surfaces in addition to providing excellent corrosion protection and chemical resistance.

Shafts and bearings

Wear and damage to shafts can be caused by a lack of lubrication, bearing failure or misalignment.

With Belzona’s metal rebuilding and repair composites, shafts can be repaired on site with minimal downtime. Bearings of all sizes can be accurately located using our cold applied epoxy compound, eliminating the need for hot work.

Pumps and valves

Damaged pumps can be restored to their original profile with Belzona cold weld metal repair composites. For precise reshaping of close tolerance areas such as wear seats, Belzona 1111 (Super Metal) multi-purpose epoxy material can be used.

Belzona 1341 (Supermetalglide) is a product in the range of epoxy coatings for corrosion and erosion protection, which reduces deterioration, increases pump efficiency and eliminates frequent maintenance costs.

Engines and enclosures

Belzona erosion and corrosion resistant materials can repair and restore engines and casings, ensuring the rapid return to service of critical equipment. Metal repair composites, such as Belzona 1111 (Super Metal), are ideal for in-situ repairs as they minimise maintenance costs and downtime compared to traditional repair methods such as welding.

Conveyor systems and rubber components

Conveyor belts can be repaired simply by using a cold-curing rubber repair material, eliminating the need for vulcanisation. Belzona elastomeric solutions can restore worn or torn areas to their original profile, providing excellent protection against wear, impact and abrasion. These multi-purpose elastomers can also be used in simple, cost-effective and durable rubber repairs for equipment such as rollers, spindles, slats and rubber hook joints on conveyor belts and other rubber components.

Our epoxy metal repair composites and coatings are suitable for other areas, including the following:

- Rebuilding of worn keyways

- Refurbishment of scored hydraulic jacks

- Restoration of loose splined bearings

- Repairing loose bearing housings

- Refurbishment of damaged threads

- Sealing of leaking tanks

Water Treatment

Belzona’s epoxy-based concrete and metal repair composites and coatings are specifically designed to repair and protect water and wastewater treatment facilities and equipment, without deviating from the relevant environmental standard.

Belzona offers a wide range of epoxy-based repair composites and coatings to repair and protect water and wastewater treatment facilities and equipment from common industry problems such as erosion, corrosion, chemical attack, mechanical damage and leaks.

Belzona solutions minimise downtime, labour and equipment replacement costs and can extend the life of assets by many years, as well as increasing their efficiency.

Repairing and improving the efficiency of fluid handling systems

Belzona offers a wide range of epoxy repair materials that can be used to repair fluid handling systems damaged by the effects of erosion, corrosion and chemical attack. Our solvent-free materials, such as Belzona 1111 (Super Metal), are formulated to restore deteriorated equipment including pumps, pipes and valves to their original profile and bond to almost any metal surface. After equipment is restored, epoxy coatings, such as Belzona 1341 (Supermetalglide), can be used to provide exceptional corrosion and erosion resistance, as well as improving equipment efficiency from 7% on new pumps to 20% on those already in service, greatly reducing operating costs.

Concrete repair of sewer systems

Our concrete repair materials and coatings are specifically designed to repair and protect sewer systems from common problems such as concrete spalling, wear and chemical attack as a result of contact with hydrogen sulphide, heavy loading and erosion. Belzona’s epoxy concrete repair materials, such as Belzona 4111 (Magma-Quartz), can repair concrete spalling on equipment including settling tanks and clarifier channels, ensuring a fast and permanent solution. Damaged installations under heavy load, such as primary settling tanks, can be repaired with high strength materials such as Belzona 4131 (Magma-Screed) and Belzona 4111 (Magma-Quartz), which bond strongly to existing concrete.

Our range of brush and spray-applied coatings, such as Belzona 5811 (Immersion Grade), provide long-term protection to a variety of equipment against corrosion and chemical attack, while ensuring easy and safe extension thanks to its solvent-free formulation.

Leak sealing

Tank and clarifier expansion joints can be easily sealed in place with Belzona 2211 (MP Hi-Build Elastomer) and Belzona 2111 (D&A Hi-Build Elastomer) elastomers. Active leaks can be sealed immediately using our epoxy repair composites, such as Belzona 1291 (ES-Metal), without the need for specialist tools or welding. In order to protect and add strength to damaged pipes, our low temperature curing pipe wrap system incorporating Belzona 1111 (Super Metal) can be used, which provides permanent pipe restoration solutions. In addition, Belzona provides protection for flanges and joints on equipment with our high strength epoxy materials such as Belzona 1111 (Super Metal) and Belzona 1121 (Super XL-Metal).

Repair and protection of mechanically damaged equipment

Costly repairs or replacement of mechanically damaged equipment such as shafts can be avoided by using Belzona epoxy repair materials, which allow in-situ repairs to be carried out without the need to dismantle the shaft, thus minimising cost and downtime. Epoxy coatings, such as Belzona 1321 (Ceramic S-Metal) and Belzona 1811 (Ceramic Carbide), are excellent for providing erosion and abrasion resistance and extending the life of equipment such as blast separators, drills and flow equipment.

Protection against chemical attack

Belzona epoxy repair composites and coatings provide excellent resistance to a wide range of damaging chemicals to equipment including chemical storage tanks and slurry dump trucks. For example, coatings such as Belzona 4311 (Magma CR1) are ideal for protecting secondary containment areas from chemicals, including acids and alkalis, and Belzona 5811 (Immersion Grade) is excellent for equipment operating under continuous immersion.

Our polymer solutions are suitable for other applications, including the following:

- Liquid-applied roofing membrane for waterproofing buildings, structures and insulation.

- Floor coating systems to protect stone and concrete floors

- Safety surfacing polymers for slip prevention and to provide satisfactory grip

Pulp and Paper

Belzona polyurethane and epoxy repair composites and coatings for the repair and protection of pulp and paper equipment against the hostile environment they face at every stage of the manufacturing process.

Belzona offers polyurethane and epoxy repair composites and coatings for the repair and protection of pulp and paper equipment susceptible to damage as a result of wear, erosion, corrosion, high temperatures and chemical attack.

Our low temperature cure materials are specifically designed to provide maintenance solutions for equipment operating in a variety of conditions, while reducing downtime, labour costs and eliminating the need for replacement.

Pump repair and protection

Severely damaged pumps in the pulp and paper sector, including liquid vacuum pumps and fan pumps can be restored to their original profile and protected against the effects of erosion, corrosion, chemical attack and deterioration using Belzona’s range of epoxy repair materials and coatings. Low temperature curing materials such as Belzona 1221 (Super E-Metal) can be used to repair broken and punctured pumps by providing excellent chemical resistance.

Our range of coatings, such as Belzona 1321 (Ceramic S-Metal), offer long-term erosion and corrosion resistance, while Belzona 1341 (Supermetalglide) is proven to increase pump efficiency by up to 7% on new equipment and up to 20% on repaired equipment.

Restoration and protection of solids handling equipment

Solids handling equipment, including screw conveyors, conveyor belts and drive rollers, which are particularly susceptible to wear due to the nature of the materials being processed, can be repaired and protected through the use of a wide range of rubber and metal repair materials. Belzona’s durable 1000 Series epoxy repair composites, such as Belzona 1811 (Ceramic Carbide), are designed to rebuild damaged screw conveyors and provide abrasion resistance for many years.

Belzona rubber repair materials, such as Belzona 2111 (D&A Hi-Build Elastomer) and Belzona 2311 (SR Elastomer), can be used for flexible repairs, including worn or broken conveyor belts and drive rollers, without dismantling the equipment. In addition, by incorporating anti-slip systems, our solutions eliminate belt slippage and protect drive rollers against abrasion and corrosion.

Repair of mechanical equipment

Mechanical equipment, such as dryer shafts and bearings, which suffer from bearing, vibration, wear and loss of lubrication can be repaired with low temperature repair materials, such as Belzona 1111 (Super Metal) and Belzona 1131 (Bearing Metal), which reduce starting friction by trapping and retaining lubrication oil. Bearing failures can be quickly repaired with fast-setting materials, such as Belzona 1221 (Super E-Metal), which is specifically designed for emergency repairs.

Evaporator and heat exchanger protection

Belzona offers a variety of epoxy materials for evaporators and heat exchangers damaged by the effects of erosion, corrosion, high temperatures and chemical attack. Our low temperature curing repair composites can be used to restore components such as tube plates, flange faces, water boxes and end covers prone to erosion and corrosion damage, including galvanic corrosion.

High temperature materials, such as Belzona 1591 (Ceramic XHT), can be used to rebuild equipment operating at temperatures up to 150°C (302°F). Belzona coatings, such as Belzona 1321 (Ceramic S-metal), are specifically designed to protect evaporators and continuous immersion heat exchangers from the forces of erosion at temperatures up to 60°C (140°F).

Repair of shredding discs

Abrasion resistant materials can be used to repair and protect worn shredder discs, which suffer from impact damage, improving the pulping process and the quality of the paper produced. Our solvent-free repair composites, such as Belzona 1311 (Ceramic R-Metal), are ideal for rebuilding worn small shredder discs, ensuring the successful production of shredded products.

Our metal repair composites and coatings are suitable for other areas including the following:

- Secondary containment areas

- Concrete and structural steel

- Pipe leaks

- Serrated rollers